CONSTRUCTION AND SIMULATION

A coarse grained Model for the Simulation of dynamic Properties of filled Elastomers

CONSTRUCTION AND SIMULATION

A coarse grained Model for the Simulation of dynamic Properties of filled Elastomers

Anbieter zum Thema

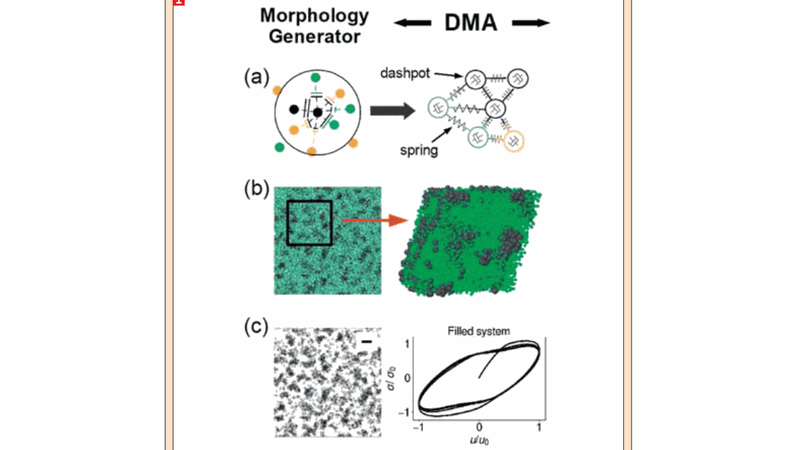

The mechanical properties of filled elastomers are strongly influenced by the distribution of filler within the polymer matrix. We describe a modelling approach to the calculation of dynamic moduli of filled elastomers based on filler morphologies derived from the experimental interface tensions of the material‘s components.

Important macroscopic performance parameters of rubber materials, e.g. rolling resistance or grip in the case of tire tread rubbers, may be correlated, albeit roughly, to the rubber‘s dynamic moduli (e.g. Refs. [1] and [2]). The latter are strongly influenced by the structure and dynamics of the interfaces between the material‘s components. Interfaces are hidden by definition and thus are difficult to study experimentally. Computer simulations, which have proven themselves as useful complement to experiments, are also apt to study the properties of filled nano-composites.

-

473,00 € / Jahr

-

Jederzeit kündbar

Sie haben bereits ein Konto? Hier einloggen

:quality(80)/p7i.vogel.de/wcms/ac/4c/ac4c91e3f302ceb89613ed910c2b0929/adobestock-292127146-4053x2283v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/58/39/5839e44836a58e3cf7d352d3210dc7d8/wdk-pressefoto-20michael-20klein-1920x1080v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6e/47/6e473ad518365a09db0d389387c5b82a/csm-banner-005-problemloesungen-01-2a8d75b173-1068x600v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/85/3b853d5a7c8fa5640146edb920e59526/pxl-20250616-161225541-mp-4032x2266v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/04/1e04e410d83b193519e83cbc2a7566ff/silpuran-medical-adhesives-2303x1295v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/42/0b/420bf691d7454a85327a80ad53c45b94/thumbnail-rado-online-strainer-1772x996v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b9/cd/b9cd9b5b904a2b3df8c5aaa7b98edc2c/kraiburg-20gummiwerk-20vmq-5712x3210v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/80/bc/80bcfb071d0b136eeb3e00a006832fbb/2026--2002--2013--20fraunhofer-20imws-20aufmacher-3024x1701v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/85/59/855967f12a6f8ff1ed20371651cb1796/screenshot-202025-12-08-20130418-690x388v1.png)

:quality(80)/p7i.vogel.de/wcms/ba/da/bada2c6c71c5232551c26cb5c7cc62e1/screenshot-202025-12-08-20131102-710x399v1.png)

:quality(80)/p7i.vogel.de/wcms/32/08/3208424a642b590ef57370b2ebb4e665/screenshot-202025-12-08-20123833-946x532v1.png)

:quality(80)/p7i.vogel.de/wcms/13/4c/134c673ee6edc454febfc844a7ede791/bildunterschrift-201-uth-trp-blending-3024x1702v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/56/075632bff9a9d7c9b5a44c50775c7d8b/aufmacher-g-c3-b6tz-scheibe-6000x3373v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/09/60095a181e6b56953727a6b89c362055/extruder-5472x3076v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/58/d8/58d87b00fb0bcda2cc265da60eab6270/4-zentr--l-c3-bcftg-ger-c3-a4t-mit-w-c3-a4rmer-c3-bcck-und-kws-3507x1973v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/02/30/02306299c3bdf32e7b856bc4e0d205bf/tempro-20basic-20120-6635x3732v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4b/5b/4b5bc2686b3643dd079a03b312ee0608/reifen-labor-abrieb-1536x864v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/9d/3b9d2095a8ebe7a56d7af8b1bc838d65/vdwf-azubi-up-01-5a70602339-1200x675v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/9d/609d1bf747c52a8a56a2f6ddf2144b43/deguma-walzwerk-aufmacher-367x206v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/23/34/23343ab8023801ac334b2f06fdeae24f/remberg-visual-copryright-remberg-5304x2983v1.png)

:fill(fff,0)/p7i.vogel.de/companies/69/84/698473213430e/logo-hpf.jpeg)