MACHINERY AND EQUIPMENTS

Additive Manufacturing of Rubber Parts based on liquid Rubber Polymers - Part 1: Design and Construction of an additive Manufacturing unit for 3D-Printing

MACHINERY AND EQUIPMENTS

Additive Manufacturing of Rubber Parts based on liquid Rubber Polymers - Part 1: Design and Construction of an additive Manufacturing unit for 3D-Printing

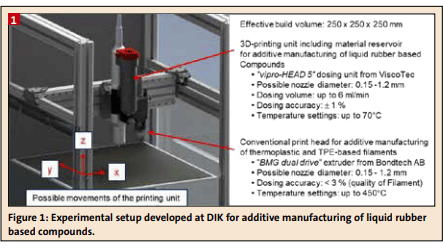

This publication describes the design and construction of a test rig for the additive manufacturing of liquid rubber-based filled and curable low viscous rubber compounds. In contrast to the previously presented AME-process [2] [3], in which conventional high viscous rubber compounds are processed in filament form via a twin-screw extruder in a modified FFF-process, the 3D-printing process of rubber compounds in this research project is realized via a dispenser unit for low-viscosity materials.

The market developments for additive manufacturing processes independently to the material clearly show the interest and the need for further innovations and solutions. The industry is in high demand for new methods and materials, seeing a market growth of average 25% since 2014 with a total estimated market value of $12,1B. This trend is further forecast with an annual growth of 24% until 2024 [1].

-

473,00 € / Jahr

-

Jederzeit kündbar

Sie haben bereits ein Konto? Hier einloggen

:quality(80)/p7i.vogel.de/wcms/3b/85/3b853d5a7c8fa5640146edb920e59526/pxl-20250616-161225541-mp-4032x2266v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a4/74/a4744b9ccd6b408173c422b918b8b11f/ulrich-reifenh-c3-a4user-3000x1688v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/72/66/72667830daf063f3e7d859498a6b0cbd/bild-2001-20gesch-c3-a4ftsf-c3-bchrung-20-c2-a9-20nexus-4032x2268v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/98/69/9869205e6343e4f9ee68360d25a0398e/aufmacher-799x449v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/42/0b/420bf691d7454a85327a80ad53c45b94/thumbnail-rado-online-strainer-1772x996v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b9/cd/b9cd9b5b904a2b3df8c5aaa7b98edc2c/kraiburg-20gummiwerk-20vmq-5712x3210v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/8d/22/8d224a120bec1c131fb630ba91178708/kraiburg-tpe-fr-1934x1087v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/85/59/855967f12a6f8ff1ed20371651cb1796/screenshot-202025-12-08-20130418-690x388v1.png)

:quality(80)/p7i.vogel.de/wcms/ba/da/bada2c6c71c5232551c26cb5c7cc62e1/screenshot-202025-12-08-20131102-710x399v1.png)

:quality(80)/p7i.vogel.de/wcms/32/08/3208424a642b590ef57370b2ebb4e665/screenshot-202025-12-08-20123833-946x532v1.png)

:quality(80)/p7i.vogel.de/wcms/9f/ce/9fce39cae6873087a7a488e41b2c99ef/screenshot-202025-12-08-20125029-700x394v1.png)

:quality(80)/p7i.vogel.de/wcms/13/4c/134c673ee6edc454febfc844a7ede791/bildunterschrift-201-uth-trp-blending-3024x1702v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/56/075632bff9a9d7c9b5a44c50775c7d8b/aufmacher-g-c3-b6tz-scheibe-6000x3373v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/09/60095a181e6b56953727a6b89c362055/extruder-5472x3076v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/58/d8/58d87b00fb0bcda2cc265da60eab6270/4-zentr--l-c3-bcftg-ger-c3-a4t-mit-w-c3-a4rmer-c3-bcck-und-kws-3507x1973v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/02/30/02306299c3bdf32e7b856bc4e0d205bf/tempro-20basic-20120-6635x3732v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4b/5b/4b5bc2686b3643dd079a03b312ee0608/reifen-labor-abrieb-1536x864v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/9d/3b9d2095a8ebe7a56d7af8b1bc838d65/vdwf-azubi-up-01-5a70602339-1200x675v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/9d/609d1bf747c52a8a56a2f6ddf2144b43/deguma-walzwerk-aufmacher-367x206v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/23/34/23343ab8023801ac334b2f06fdeae24f/remberg-visual-copryright-remberg-5304x2983v1.png)