CONSTRUCTION AND SIMULATION

Applied Resource Efficiency and Lightweight Design for a Sealing Ring

CONSTRUCTION AND SIMULATION

Applied Resource Efficiency and Lightweight Design for a Sealing Ring

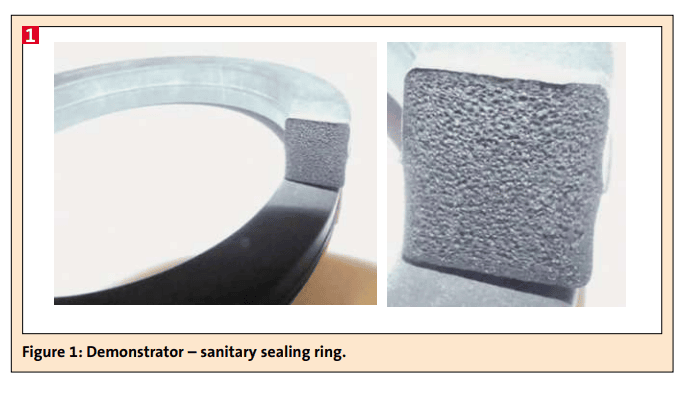

Due to their energy-intensive manufacturing process and low recyclability rubber parts offer great potential for reducing material use and carbon footprint. Therefore, different approaches were investigated with the aim to reduce the resource use of a rubber sealing ring while maintaining specifications. The combination of bio-based and high-performance polymers and fillers, the foaming of rubbers using microspheres and a load-specific design enabled savings in weight of up to 26%.

Introduction In order to achieve the climate targets set in Germany and the EU, industries like automotive and construction are required to drastically reduce the carbon footprint of their products. Lightweight construction technologies represent a key strategy to achieve these objectives. This includes the use of new design techniques and manufacturing technologies, as well as the implementation of sustainable materials and improved resource efficiency of existing materials.

-

473,00 € / Jahr

-

Jederzeit kündbar

Sie haben bereits ein Konto? Hier einloggen

:quality(80)/p7i.vogel.de/wcms/3b/85/3b853d5a7c8fa5640146edb920e59526/pxl-20250616-161225541-mp-4032x2266v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a4/74/a4744b9ccd6b408173c422b918b8b11f/ulrich-reifenh-c3-a4user-3000x1688v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/72/66/72667830daf063f3e7d859498a6b0cbd/bild-2001-20gesch-c3-a4ftsf-c3-bchrung-20-c2-a9-20nexus-4032x2268v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/98/69/9869205e6343e4f9ee68360d25a0398e/aufmacher-799x449v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/04/1e04e410d83b193519e83cbc2a7566ff/silpuran-medical-adhesives-2303x1295v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/42/0b/420bf691d7454a85327a80ad53c45b94/thumbnail-rado-online-strainer-1772x996v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b9/cd/b9cd9b5b904a2b3df8c5aaa7b98edc2c/kraiburg-20gummiwerk-20vmq-5712x3210v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/85/59/855967f12a6f8ff1ed20371651cb1796/screenshot-202025-12-08-20130418-690x388v1.png)

:quality(80)/p7i.vogel.de/wcms/ba/da/bada2c6c71c5232551c26cb5c7cc62e1/screenshot-202025-12-08-20131102-710x399v1.png)

:quality(80)/p7i.vogel.de/wcms/32/08/3208424a642b590ef57370b2ebb4e665/screenshot-202025-12-08-20123833-946x532v1.png)

:quality(80)/p7i.vogel.de/wcms/9f/ce/9fce39cae6873087a7a488e41b2c99ef/screenshot-202025-12-08-20125029-700x394v1.png)

:quality(80)/p7i.vogel.de/wcms/13/4c/134c673ee6edc454febfc844a7ede791/bildunterschrift-201-uth-trp-blending-3024x1702v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/56/075632bff9a9d7c9b5a44c50775c7d8b/aufmacher-g-c3-b6tz-scheibe-6000x3373v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/09/60095a181e6b56953727a6b89c362055/extruder-5472x3076v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/58/d8/58d87b00fb0bcda2cc265da60eab6270/4-zentr--l-c3-bcftg-ger-c3-a4t-mit-w-c3-a4rmer-c3-bcck-und-kws-3507x1973v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/02/30/02306299c3bdf32e7b856bc4e0d205bf/tempro-20basic-20120-6635x3732v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4b/5b/4b5bc2686b3643dd079a03b312ee0608/reifen-labor-abrieb-1536x864v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/9d/3b9d2095a8ebe7a56d7af8b1bc838d65/vdwf-azubi-up-01-5a70602339-1200x675v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/9d/609d1bf747c52a8a56a2f6ddf2144b43/deguma-walzwerk-aufmacher-367x206v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/23/34/23343ab8023801ac334b2f06fdeae24f/remberg-visual-copryright-remberg-5304x2983v1.png)