ELASTOMERS AND PLASTICS

Long Chain Branching for Ethylene-Propylene-Diene Rubber: a fast and accurate measurement method

ELASTOMERS AND PLASTICS

Long Chain Branching for Ethylene-Propylene-Diene Rubber: a fast and accurate measurement method

Anbieter zum Thema

Modern catalyst systems enable us to synthesize ethylene-propylene-diene polymers with well-defined properties. For example, the degree of polymer branching can be precisely adjusted to enhance the processability of rubber compounds. In this work, we compare four commonly used parameters obtained from Mooney stress relaxation, and frequency sweep, and amplitude sweep measurements.

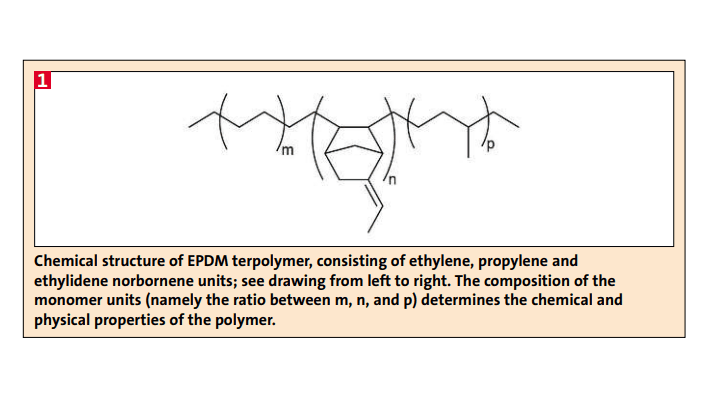

Ethylene-propylene-diene (EPDM) polymers (Figure 1) represent the most widespread non-tire rubber in terms of volume and number of applications. Heavily used in the automotive and construction sector, EPDM products undergo continuous developments to meet the increasingly more demanding requirements in terms of sustainability and performance, with emphasis towards both the manufacturing processes and the final products [1–3].

-

473,00 € / Jahr

-

Jederzeit kündbar

Sie haben bereits ein Konto? Hier einloggen

:quality(80)/p7i.vogel.de/wcms/ac/4c/ac4c91e3f302ceb89613ed910c2b0929/adobestock-292127146-4053x2283v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/58/39/5839e44836a58e3cf7d352d3210dc7d8/wdk-pressefoto-20michael-20klein-1920x1080v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6e/47/6e473ad518365a09db0d389387c5b82a/csm-banner-005-problemloesungen-01-2a8d75b173-1068x600v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/85/3b853d5a7c8fa5640146edb920e59526/pxl-20250616-161225541-mp-4032x2266v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/04/1e04e410d83b193519e83cbc2a7566ff/silpuran-medical-adhesives-2303x1295v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/42/0b/420bf691d7454a85327a80ad53c45b94/thumbnail-rado-online-strainer-1772x996v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b9/cd/b9cd9b5b904a2b3df8c5aaa7b98edc2c/kraiburg-20gummiwerk-20vmq-5712x3210v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/80/bc/80bcfb071d0b136eeb3e00a006832fbb/2026--2002--2013--20fraunhofer-20imws-20aufmacher-3024x1701v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/85/59/855967f12a6f8ff1ed20371651cb1796/screenshot-202025-12-08-20130418-690x388v1.png)

:quality(80)/p7i.vogel.de/wcms/ba/da/bada2c6c71c5232551c26cb5c7cc62e1/screenshot-202025-12-08-20131102-710x399v1.png)

:quality(80)/p7i.vogel.de/wcms/32/08/3208424a642b590ef57370b2ebb4e665/screenshot-202025-12-08-20123833-946x532v1.png)

:quality(80)/p7i.vogel.de/wcms/13/4c/134c673ee6edc454febfc844a7ede791/bildunterschrift-201-uth-trp-blending-3024x1702v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/56/075632bff9a9d7c9b5a44c50775c7d8b/aufmacher-g-c3-b6tz-scheibe-6000x3373v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/09/60095a181e6b56953727a6b89c362055/extruder-5472x3076v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/58/d8/58d87b00fb0bcda2cc265da60eab6270/4-zentr--l-c3-bcftg-ger-c3-a4t-mit-w-c3-a4rmer-c3-bcck-und-kws-3507x1973v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/02/30/02306299c3bdf32e7b856bc4e0d205bf/tempro-20basic-20120-6635x3732v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4b/5b/4b5bc2686b3643dd079a03b312ee0608/reifen-labor-abrieb-1536x864v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/9d/3b9d2095a8ebe7a56d7af8b1bc838d65/vdwf-azubi-up-01-5a70602339-1200x675v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/9d/609d1bf747c52a8a56a2f6ddf2144b43/deguma-walzwerk-aufmacher-367x206v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/23/34/23343ab8023801ac334b2f06fdeae24f/remberg-visual-copryright-remberg-5304x2983v1.png)

:fill(fff,0)/p7i.vogel.de/companies/69/84/698473213430e/logo-hpf.jpeg)