ELASTOMERS AND PLASTICS

Modelling of the Filler Incorporation during the Rubber Mixing Process using EPDM

ELASTOMERS AND PLASTICS

Modelling of the Filler Incorporation during the Rubber Mixing Process using EPDM

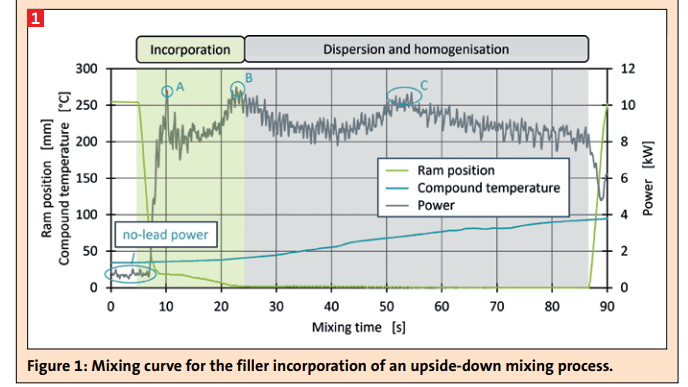

Rubber compounds consisting of various components such as rubber, fillers, plasticisers and other additives are produced in a discontinuously working internal mixer. To ensure a high quality of the product, mixing instructions are developed for each recipe. Based on existing mathematical models, describing the ram position and torque curve of the internal mixer during filler incorporation, physically inspired correlations will be integrated.

Rubber compounds are almost exclusively produced in discontinuously working internal mixers. This offers the advantages of high flexibility and the ability to accept a variety of different dosing components (bales, powder, oil, etc.).

-

473,00 € / Jahr

-

Jederzeit kündbar

Sie haben bereits ein Konto? Hier einloggen

:quality(80)/p7i.vogel.de/wcms/3b/85/3b853d5a7c8fa5640146edb920e59526/pxl-20250616-161225541-mp-4032x2266v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a4/74/a4744b9ccd6b408173c422b918b8b11f/ulrich-reifenh-c3-a4user-3000x1688v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/72/66/72667830daf063f3e7d859498a6b0cbd/bild-2001-20gesch-c3-a4ftsf-c3-bchrung-20-c2-a9-20nexus-4032x2268v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/98/69/9869205e6343e4f9ee68360d25a0398e/aufmacher-799x449v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/42/0b/420bf691d7454a85327a80ad53c45b94/thumbnail-rado-online-strainer-1772x996v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b9/cd/b9cd9b5b904a2b3df8c5aaa7b98edc2c/kraiburg-20gummiwerk-20vmq-5712x3210v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/8d/22/8d224a120bec1c131fb630ba91178708/kraiburg-tpe-fr-1934x1087v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/85/59/855967f12a6f8ff1ed20371651cb1796/screenshot-202025-12-08-20130418-690x388v1.png)

:quality(80)/p7i.vogel.de/wcms/ba/da/bada2c6c71c5232551c26cb5c7cc62e1/screenshot-202025-12-08-20131102-710x399v1.png)

:quality(80)/p7i.vogel.de/wcms/32/08/3208424a642b590ef57370b2ebb4e665/screenshot-202025-12-08-20123833-946x532v1.png)

:quality(80)/p7i.vogel.de/wcms/9f/ce/9fce39cae6873087a7a488e41b2c99ef/screenshot-202025-12-08-20125029-700x394v1.png)

:quality(80)/p7i.vogel.de/wcms/13/4c/134c673ee6edc454febfc844a7ede791/bildunterschrift-201-uth-trp-blending-3024x1702v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/56/075632bff9a9d7c9b5a44c50775c7d8b/aufmacher-g-c3-b6tz-scheibe-6000x3373v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/09/60095a181e6b56953727a6b89c362055/extruder-5472x3076v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/58/d8/58d87b00fb0bcda2cc265da60eab6270/4-zentr--l-c3-bcftg-ger-c3-a4t-mit-w-c3-a4rmer-c3-bcck-und-kws-3507x1973v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/02/30/02306299c3bdf32e7b856bc4e0d205bf/tempro-20basic-20120-6635x3732v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4b/5b/4b5bc2686b3643dd079a03b312ee0608/reifen-labor-abrieb-1536x864v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/9d/3b9d2095a8ebe7a56d7af8b1bc838d65/vdwf-azubi-up-01-5a70602339-1200x675v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/9d/609d1bf747c52a8a56a2f6ddf2144b43/deguma-walzwerk-aufmacher-367x206v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/23/34/23343ab8023801ac334b2f06fdeae24f/remberg-visual-copryright-remberg-5304x2983v1.png)