TESTING AND MEASURING

New Thermoset Capillary Rheometer (TCR) to evaluate Flow and Thermal Behavior of thermosets

TESTING AND MEASURING

New Thermoset Capillary Rheometer (TCR) to evaluate Flow and Thermal Behavior of thermosets

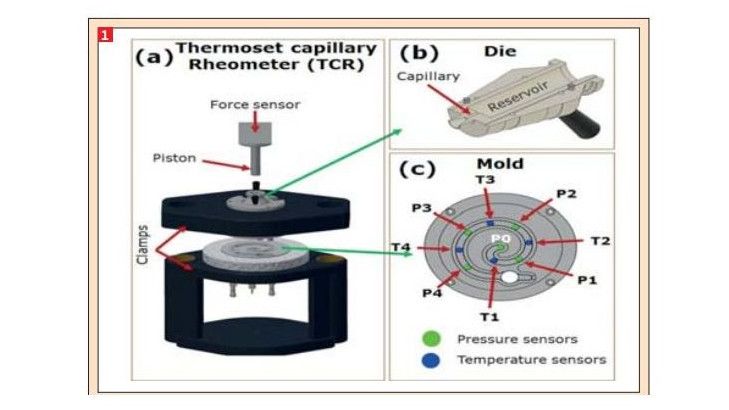

To evaluate flow and thermal properties of thermosetting materials at pressures comparable to processing operations, a new Thermoset Capillary Rheometer (TCR) is introduced. Material viscosity is measured before curing and during curing.

(Bild: Dätwyler, Schattdorf, Schweiz)

Capillary rheometer measures flow properties of viscoelastic materials in shear and elongation at high strain rates. Steady-state shear viscosity is measured by pressure difference at the two ends of a capillary or a slit die. Steady-state first normal stress difference is also measured in a capillary rheometer via an addon known as normal stress die.

-

473,00 € / Jahr

-

Jederzeit kündbar

Weitere Angebote erkunden

Sie haben bereits ein Konto? Hier einloggen

:quality(80)/p7i.vogel.de/wcms/3b/85/3b853d5a7c8fa5640146edb920e59526/pxl-20250616-161225541-mp-4032x2266v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a4/74/a4744b9ccd6b408173c422b918b8b11f/ulrich-reifenh-c3-a4user-3000x1688v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/72/66/72667830daf063f3e7d859498a6b0cbd/bild-2001-20gesch-c3-a4ftsf-c3-bchrung-20-c2-a9-20nexus-4032x2268v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/98/69/9869205e6343e4f9ee68360d25a0398e/aufmacher-799x449v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/42/0b/420bf691d7454a85327a80ad53c45b94/thumbnail-rado-online-strainer-1772x996v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b9/cd/b9cd9b5b904a2b3df8c5aaa7b98edc2c/kraiburg-20gummiwerk-20vmq-5712x3210v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/8d/22/8d224a120bec1c131fb630ba91178708/kraiburg-tpe-fr-1934x1087v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/85/59/855967f12a6f8ff1ed20371651cb1796/screenshot-202025-12-08-20130418-690x388v1.png)

:quality(80)/p7i.vogel.de/wcms/ba/da/bada2c6c71c5232551c26cb5c7cc62e1/screenshot-202025-12-08-20131102-710x399v1.png)

:quality(80)/p7i.vogel.de/wcms/32/08/3208424a642b590ef57370b2ebb4e665/screenshot-202025-12-08-20123833-946x532v1.png)

:quality(80)/p7i.vogel.de/wcms/9f/ce/9fce39cae6873087a7a488e41b2c99ef/screenshot-202025-12-08-20125029-700x394v1.png)

:quality(80)/p7i.vogel.de/wcms/13/4c/134c673ee6edc454febfc844a7ede791/bildunterschrift-201-uth-trp-blending-3024x1702v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/56/075632bff9a9d7c9b5a44c50775c7d8b/aufmacher-g-c3-b6tz-scheibe-6000x3373v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/09/60095a181e6b56953727a6b89c362055/extruder-5472x3076v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/58/d8/58d87b00fb0bcda2cc265da60eab6270/4-zentr--l-c3-bcftg-ger-c3-a4t-mit-w-c3-a4rmer-c3-bcck-und-kws-3507x1973v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/02/30/02306299c3bdf32e7b856bc4e0d205bf/tempro-20basic-20120-6635x3732v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4b/5b/4b5bc2686b3643dd079a03b312ee0608/reifen-labor-abrieb-1536x864v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/3b/9d/3b9d2095a8ebe7a56d7af8b1bc838d65/vdwf-azubi-up-01-5a70602339-1200x675v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/9d/609d1bf747c52a8a56a2f6ddf2144b43/deguma-walzwerk-aufmacher-367x206v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/23/34/23343ab8023801ac334b2f06fdeae24f/remberg-visual-copryright-remberg-5304x2983v1.png)