Was tut sich in den Laboren von Universitäten oder F&E-Abteilungen der Unternehmen? In exklusiven Publikationen teilen Wissenschaftler aus aller Welt ihre aktuellen Erkenntnisse.

Properties of ultrasonically devulcanized and revulcanized used Tire Rubber and their Blends with virgin natural Rubber

The continuous ultrasonic devulcanization of 40 mesh ground tire rubber (GTR) powder was carried out using an ultrasonically assisted twin-screw extruder. The die pressure and ultrasonic power consumption were recorded during the process. The gel fraction, crosslink density and revulcanization behavior were studied to investigate the degree of devulcanization. Untreated tire rubber (UTR) powder and ground tire rubbers after devulcanization were blended with natural rubber (NR) at different ratios Rheological properties, curing behavior, mechanical properties and abrasion loss of revulcanized rubbers were measured.Weiterlesen...

Tribological and mechanical Performance of HDPE/SWCNT Nanocomposites as Bearing Material

The nano-composite samples were prepared to the cylindrical shape and subjected to friction and wear tests using pin on disc tribometer. The samples were evaluated via examining the hardness, modulus of elasticity, and compressive yield stress. The results revealed that adding 0.4% by weight of SWCNT leads to improving the tribological and mechanical performance of HDPE matrix. It can be evident that the friction coefficient and weight loss were reduced with 20% and 24%, respectively, compared with pure sample. It can be noticed from the experiments that the modulus of elasticity and compressive yield stress increase about 25.6% and 57%, respectively.Weiterlesen...

Optimization of Pressure and throughput Fluctuations of a cold-fed Rubber Extruder by means of a separately driven Feed Roller

In rubber extrusion, stable pressure and throughput over time is of central importance for the quality of the extrudate. One challenge is the non-uniform material intake of feed strips. Variable feed behaviour causes pressure and throughput fluctuations in the feed zone, which propagate to the die and may lead to dimensional deviations of the extrudate. The feed roller speed can influence the intake of the feed strip and therefore help to keep steady the pressure in the feed zone. Thanks to a measurement of the drive torques from the screw and the feed roller, deviations in the feeding can quickly be identified.Weiterlesen...

Modelling Study of Reinforcement and Rupture in Strain Crystallizing Elastomer Networks

The model for strain-induced crystallization (SIC) in elastomer networks proposed by Plagge and Hentschke [1] is extended for the simulation of rupture. A critical force for rupture of links, i.e. the polymer chains in the model network, is defined. The variation of parameters which affect the structure of the networks or the free energy of the links has not improved the tensile strength of strain-crystallizing networks compared to non-crystallizing networks in both the 2D- and the 3D-case. Thus, a critical crystallinity is introduced. If the crystallinity of a link exceeds this threshold, the link becomes unbreakable. The tensile strength of crystallizing 2D- and 3D-networks has improved significantly.Weiterlesen...

Sophisticated Vulcanization of Rubber

This paper presents of sophisticated aspects of the N-(1,3-benzothiazol-2-ylsulfanyl)cyclohexanamine-accelerated vulcanization of isoprene rubber (IR) as a mini-reviewed, where zinc oxide (ZnO), stearic acid (StH) and/or zinc stearate are used as activators. The combination of these activators enables the control of the mesh size in the network, where new complexes are generated by a reaction of ZnO with StH, or by zinc stearate near the vulcanization temperature. The complexes accelerate the sulfur cross-linking of IR like an enzyme. An electron-transfer and a dispersion effects of IR for the complexes play roles of the acceleration of cross-linking and the formation of homogeneous network structure, respectively. In addition, the complexes predominantly generate the disulfidic linkages in the sulfur cross-linking.Weiterlesen...

Tire Wear Particles

Tire wear significantly contributes to the growing amount of microplastic in the environment. It is found in the waters and in the soils, meanwhile also in living beings.Weiterlesen...

Numerical Studies on the Dissipation behavior of Elastomers and its Effect on the applied loading Conditions

The aim of this paper is to discuss the effect of the viscoelasticity and dissipation behavior of elastomers on the applied loading conditions. For that purpose, the loading applied on the rotary dynamic testing machine designed by Gent [1] is simulated. The material model used in the simulation is a finite viscoelastic model based on the multiplicative decomposition of the deformation gradient.Weiterlesen...

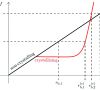

Similarities in Stress-Strain-Curve and electrical Conductivity

Electroconductive composites were prepared using either styrene–butadiene rubber or polycaprolactone matrix with varying amounts of two grades of electroconductive carbon black. Electrical conductivity was measured during deformation and at the same time a stress-strain-curve was recorded. The dependences of electrical conductivity on deformation exhibit several extremes. All conductivity changes were interpreted in terms of either the conductive pathways destruction or the formation of new ones, Thus, electrical conductivity can be correlated with the specific features of the physical network of the reinforcing filler that affect the mechanical properties of the composite.Weiterlesen...

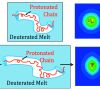

Molecular-Scale Polymer Melts Response to shear in the linear and non-linear rheological

The molecular-level response to shear of entangled polymers at interfaces and in the bulk has been of interest to understand the non-linear rheological response of polymers. Here we focus on the molecular level response to shear strain leading non-linear rheological phenomenon, in linear and star polymers comparing the observed response to the predictions of tube theory. We used SANS measurements of the bulk polymer response to shear in Couette geometry on melts of high molecular weight mixtures of polymers extending our previous results on interfacial responses with rheoNR measurements in cone-and-plate geometry.[1, 2] further development of the theory.Weiterlesen...

Influence of Process Parameters on the Curing of Polyurethanes by dielectric Measurements

The Polyurethane Reaction Injection Molding (PU RIM) process is currently still reliant on a high level of know-how, both in the case of quality deviations of the product and in the initial configuration of molds. PU manufacturing hardly uses the established sensor technologies that are common in injection molding. In a research project at the Institute for Plastics Processing (IKV), the influence of the process parameters component temperature, mold temperature, material output speed and mixing ratio on the curing behavior of compact polyurethane coating systems is being experimentally investigated by means of dielectric measurements. The results show that for all variations of the process parameters investigated, the influence on the curing reaction could be successfully detected.Weiterlesen...